In the ever-evolving landscape of dental prosthetics, precision, efficiency, and material adaptability are no longer optional—they’re necessities. Enter the wet dental CAD/CAM machine, a powerhouse technology redefining laboratory workflows by seamlessly milling a broad spectrum of materials, from titanium blocks to zirconia, wax, and PMMA. For laboratories and technicians seeking a 2-in-1 wet and dry milling solution that marries versatility with reliability, Dental Laboratorio offers the ultimate answer—backed by expert installation, tutorials, and operational guides.

Why Wet Milling Matters: The Secret to Material Mastery

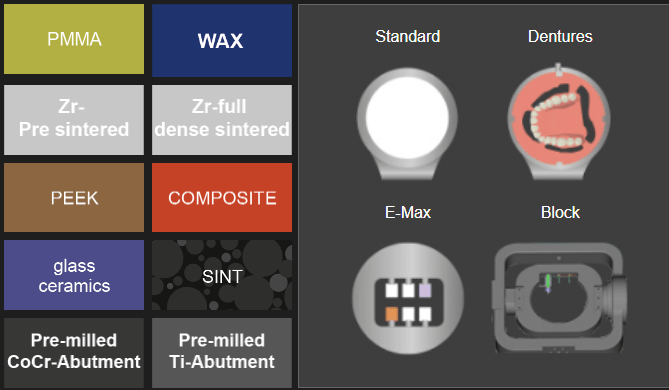

Wet milling isn’t just a niche technique—it’s a game-changer for dental labs. By integrating water or coolant into the milling process, these machines dissipate heat, reduce tool wear, and enhance surface finishes. But their true superpower lies in their ability to handle diverse materials without compromising on quality. Here’s why wet dental CAD/CAM machines are the Swiss Army knife of modern prosthodontics:

1. Titanium Blocks: Strength Meets Precision

Titanium’s biocompatibility and strength make it ideal for implants and frameworks. However, its thermal sensitivity and gumminess during milling pose challenges. Wet milling solves this:

- Coolant Protection: Water prevents overheating, avoiding titanium’s risk of oxidation or microstructural changes.

- Lubrication: Reduces friction, ensuring smooth cuts and extended tool life.

- Surface Excellence: Delivers a polished finish critical for implants, eliminating secondary polishing steps.

2. Wax: The Foundation of Accurate Models

Wax patterns demand meticulous detail for diagnostic wax-ups and cast models. Wet milling ensures:

- No Heat Deformation: Wax melts easily, but water cooling keeps temperatures in check.

- Fine Details Preserved: Enhanced lubrication allows intricate designs (clasps, occlusal surfaces) to emerge flawlessly.

3. Zirconia: The Workhorse of Modern Dentistry

While zirconia is often milled dry due to its thermal stability, wet milling shines for specific cases:

- High-Translucency Monolithic Restorations: Water prevents microcracks in thinner, highly aesthetic zirconia blanks.

- Tool Longevity: Coolant reduces wear on diamond-coated burs, maximizing ROI.

4. PMMA (Acrylic) Blocks: Dentures Made Easy

PMMA’s affordability and ease of use come with a caveat—heat buildup. Wet milling:

- Prevents Melting: Coolant keeps acrylic stable, avoiding warping or bubble formation.

- Smooth Surfaces: Eliminates the need for manual finishing, saving time and effort.

Beyond Wet Milling: The 2-in-1 Advantage

The best wet dental CAD/CAM machines offer dual functionality, switching between wet and dry milling as needed. Why does this matter?

- Material Flexibility: Mill zirconia dry (for speed) and titanium wet (for safety) without switching machines.

- Efficiency: Dry milling suits heat-resistant materials (e.g., cobalt-chrome), while wet mode handles everything else.

- Cost-Effectiveness: One machine replaces multiple units, freeing up bench space and budget.

Why Choose Dental Laboratorio’s Wet CAD/CAM Solution?

At Dental Laboratorio, we don’t just sell machines—we empower labs to thrive. Our wet and dry 2-in-1 dental milling machines come with:

- Installation & Training: Expert setup and step-by-step tutorials for technicians.

- Material Compatibility: Engineered to mill titanium, zirconia, wax, PMMA, and more.

- Precision at Every Step: Advanced software integration for flawless design-to-milling workflows.

- Support You Can Trust: Manuals, troubleshooting guides, and customer support tailored to dental labs.

A Future-Ready Investment

For laboratories tired of juggling specialized machines or technicians stressed by material limitations, a wet dental CAD/CAM machine is the upgrade you’ve been searching for. Whether you’re crafting monolithic zirconia crowns, titanium implants, or dentures, this technology ensures every restoration meets clinical and aesthetic standards.

Ready to Revolutionize Your Lab?

Visit Dental Laboratorio to explore our range of wet and dry Dental CAD/CAM milling machines. With installation tutorials, manual guides, and a commitment to your success, we’re here to turn your next prosthesis into a masterpiece. For laboratories and technicians looking for this versatile wet and dry 2-in-one unit dental milling machine, look no further than Dental Laboratorio.

Leave a comment