Traditional dental restoration has long relied on a series of intricate, labor-intensive steps. From the physical impression using putty-like materials to the meticulous hand-fabrication of prosthetics by skilled dental technicians in off-site labs, the process was time-consuming and highly dependent on individual expertise. While effective, this conventional approach often required multiple appointments spread across several weeks, leaving patients with temporary restorations in the interim.

Enter the digital age of dentistry, a transformative era driven by CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) technology. This paradigm shift has streamlined the restorative process, offering unprecedented efficiency, precision, and the exciting possibility of same-day crowns and bridges. At the heart of this revolution are advanced CAD/CAM blocks, the essential raw material for creating high-quality, durable, and aesthetic dental prosthetics.

The digital workflow begins with capturing a highly accurate digital impression of the patient’s mouth using an intraoral scanner. This eliminates the discomfort and potential inaccuracies associated with traditional impressions. The digital scan is then imported into CAD software, where the dental professional designs the restoration with remarkable precision, considering factors like occlusion, contacts, and aesthetics. Once the design is finalized, the information is sent to a CAM unit – a milling machine – which precisely carves the restoration from a solid CAD/CAM block.

This integrated digital process significantly reduces the time and steps involved compared to the traditional method. There’s no need for physical models, articulators, or the back-and-forth shipping to an external lab. This efficiency is a key enabler of same-day dentistry, allowing patients to receive their permanent crowns or bridges in a single visit, a significant advantage for both patient convenience and practice productivity.

Among the various materials available for CAD/CAM milling, zirconia has emerged as a leading choice, widely favored for its exceptional strength, durability, and biocompatibility. Zirconia blocks are the foundation for creating robust restorations capable of withstanding the demanding forces of mastication, making them ideal for both anterior and posterior crowns and bridges.

For dental practices embracing the full digital workflow, in-office CAD/CAM systems like the Sirona CEREC are particularly characteristic. These compact milling units are designed to be housed directly within the dental office, enabling the entire process, from scanning and design to milling and sintering, to be completed chairside. Coupled with advanced fast-sintering furnaces specifically designed for zirconia, these systems empower dentists to deliver high-quality, metal-free zirconia restorations, sometimes including multi-unit bridges, within a single appointment.

Recognizing the growing need for high-quality, compatible materials within this digital ecosystem, Dental Lab Shop offers a range of CAD/CAM blocks specifically designed to work seamlessly with systems like Sirona CEREC. Their zirconia blocks are engineered to meet the rigorous demands of modern restorative dentistry, providing dental professionals with reliable and aesthetic options for their patients.

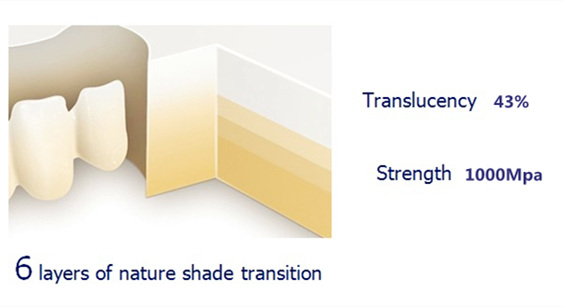

Key features of Dental Lab Shop’s CAD/CAM blocks include impressive material properties essential for successful and long-lasting restorations. With a transparency of 43%, these blocks allow for a natural light transmission, contributing to the lifelike appearance of the final prosthetic. Furthermore, boasting a bending strength of 1000MPa, these blocks are robust enough for a wide range of applications, including full contour crowns and bridges, ensuring structural integrity and longevity.

Beyond strength and translucency, aesthetics are paramount in dental restorations. Dental Lab Shop’s CAD/CAM blocks are available in multilayer options, which feature a highly aesthetic color gradient that transitions progressively and seamlessly from the cervical to the incisal area. This mimics the natural shading of teeth, resulting in restorations that blend harmoniously with the patient’s existing dentition. With 20 color options available, including popular bleach shades, dental professionals have the versatility to achieve precise color matching for a truly individualized and aesthetic outcome.

In conclusion, the integration of CAD/CAM technology and advanced materials like zirconia CAD CAM blocks has revolutionized dental restorations. The digital workflow offers unparalleled efficiency, allowing for the realization of same-day crowns and bridges and eliminating many of the traditional complexities. Products like the CAD CAM blocks from Dental Lab Shop, specifically designed for compatibility with leading in-office systems like Sirona CEREC and featuring excellent strength, transparency, and aesthetic options, are vital components in this modern approach to providing patients with high-quality, durable, and beautiful dental prosthetics.

Leave a comment